From Sketch to Solution: Turning Your Custom Fabrication Idea into a Finished Part

- michael6327

- Aug 8, 2025

- 3 min read

Updated: Aug 12, 2025

Your Idea, Our Craft

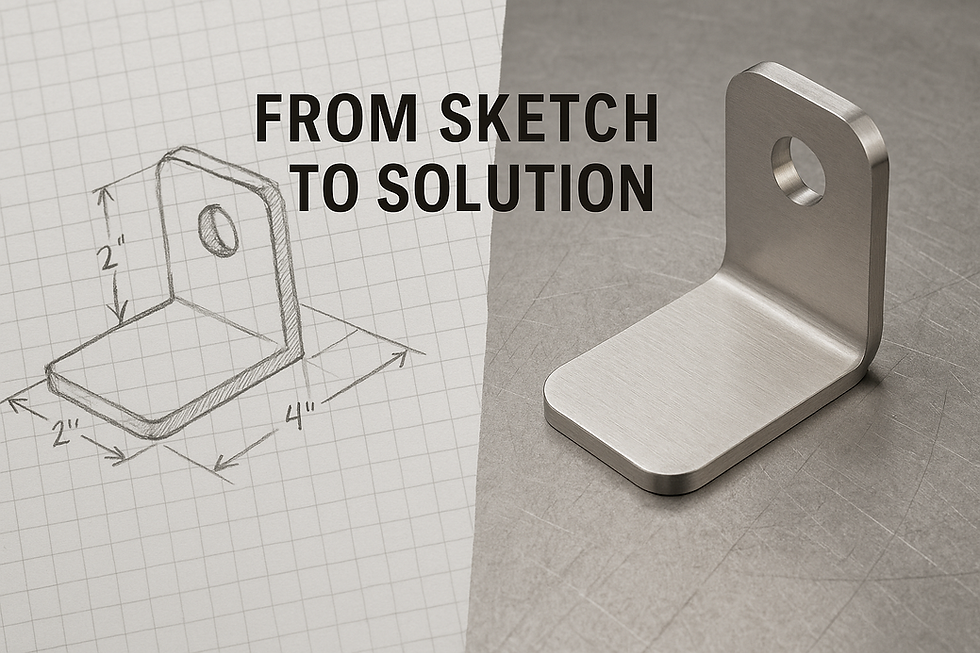

You’ve got a problem to solve, a project in mind, or a part that just doesn’t exist in any catalog. Maybe you’ve got a quick doodle on a napkin, or maybe it’s been rattling around in your head for months. That’s where Franklin Sheet Metal steps in — taking that idea and turning it into something you can hold, bolt, weld, or install.

We live in that sweet spot where creativity meets precision. Here’s how we take your project from “rough sketch” to a fully finished, ready-to-use part — and why having a team like ours in your back pocket can make all the difference.

Step 1: The Conversation — Understanding the Problem

Every project starts with a conversation. We don’t just look at a drawing and nod; we ask questions:

What’s the part for?

What environment will it live in?

What’s the “must-have” versus the “nice-to-have”?

You might come in thinking you need stainless steel, but we’ll talk you through whether aluminum or carbon steel might be a better fit. Sometimes a small change in material or thickness can save you cost, weight, and future headaches.

Step 2: The Sketch — Getting Your Idea on Paper

Here’s the truth: bring a sketch. Even a rough hand drawing that shows your design intent is better than showing up empty-handed. It doesn’t have to be perfect or to scale, but it should have most of the key dimensions.

Why? Because it:

Speeds up your quote

Prevents unnecessary headaches later

Avoids mismatched expectations

Gives us something real to work from

We can’t build something that only exists in your head. And trust us — we’ve lost count of the times someone’s walked in saying, “Hey, can you make this?” and we’re like… “Oook… what is it?”

Come prepared. Know the metal you want — stainless, aluminum, or steel — and we’ll take it from there.

Step 3: Engineering for Fabrication

This is where we make sure your design wants to be made. Even the simplest part has details that matter — bend radii, weld clearance, fastener spacing, surface finish, and tolerances.

At this stage, we:

Confirm material choice (steel, stainless, aluminum)

Determine bend allowances

Plan weld locations

Decide on powder coat, plating, or polishing

Ensure the design works with our tooling and processes

If your part is designed to fight the machines, the machines usually win — and costs go up.

Step 4: Prototyping (When It’s Needed)

Not every job needs a prototype, but when it does, it’s worth the extra step. We’ll cut, bend, weld, and finish a one-off piece so you can test it in the real world.

Prototyping helps:

Verify fit before committing to production

Test strength and functionality

Make last-minute adjustments

For some projects, the prototype is the end product. For others, it’s a stepping stone to a short or long production run.

Step 5: Fabrication — Where Sparks Fly

Once the design is locked in, it’s time to make chips and sparks. In our shop, fabrication might include:

Laser cutting or waterjet cutting

CNC punching and forming

TIG, MIG, or spot welding

Hardware installation (PEMs, studs, etc.)

Surface finishing — from brushed stainless to durable powder coat

This is where the shop hums, the metal moves, and your idea turns into something tangible.

Every Shop is Different

Here’s a reality check: every fabrication shop has its own specialties, equipment, and limitations. We wish we could do it all — and we like to think we can — but proper planning makes all the difference.

The better prepared you are, the easier it is for us to say “yes” and deliver exactly what you need. And if your project calls for capabilities outside our four walls, we’re happy to work with other shops to make it happen.

Final Word

Turning a sketch into a finished part isn’t just about tools and machines — it’s about understanding your needs, designing for manufacturability, and executing with precision. That’s what we do at Franklin Sheet Metal, day in and day out.

So next time you’ve got an idea that lives in the “who can make this?” category… you know who to call.

Comments